During this training the student will advance his her practical skills and understanding of sheet metal structure fabrication and repair according manufacturer documentation.

Aviation sheet metal training.

Writes programs for cnc machines using manual and computer aided design computer aided manufacturing cad cam.

Students spend time in the classroom learning terminology tools equipment blueprint reading and shop safety before moving into the shop for hands on experience.

This second portion of the class focuses on advanced aviation sheet metal skills.

About this major aviation sheet metal focuses on teaching basic aircraft sheet metal skills.

Part of this time is spent in the classroom and in the field.

Welds brazes solders and heat treats metals.

Jack is a sheet metal construction expert and serves on the eaa homebuilt council the eaa canadian council and is an eaa technical counselor.

Engine disassembly and repair.

Some of the skills you ll learn are.

Many thanks friday december 13 2019 cargolux luxembourg the technicians of cargolux has followed a 5 week aircraft structure training.

It is therefore important to train how to apply sealant compound properly view training 980 basic metallic aircraft structure manufacturing inspection and repair of metallic aircraft structures the sheet metal aircraft is exposed to enormous forces during take off flight and landing and will get damaged.

Aircraft sheet metal mechanics fit and assemble parts of airplanes and space vehicles.

Upon completion of training the student will be able to assist experienced structures technicians in the aircraft line or base maintenance environment.

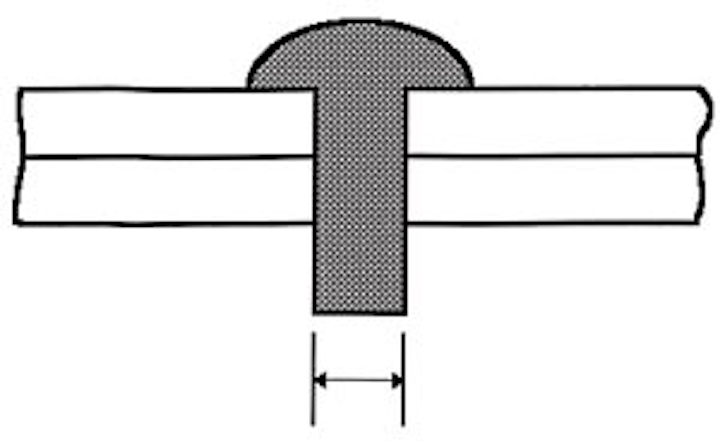

Findings 3 2 theory 1 exercises on aircraft sheet metal repair damage evaluation.

Job training for an aircraft structural repairer requires 10 weeks of basic combat training and 15 weeks of advanced individual training with on the job instruction.

Upon completion of training the student will gain the skills and confidence needed to work in an aircraft maintenance environment in a structures team under supervision.

Training is performed primarily on large aircraft.

Aircraft sheet metal mechanic resume examples.

Composite awareness composite is a very sensitive material and technicians should have the knowledge to prevent damage and ex pensive repairs.

Typical duties listed on a resume sample for aircraft sheet metal mechanic include reading blueprints trimming parts maintaining system components inspecting and testing units verifying tension of cables and capturing waste materials.

During this training the student will develop basic practical skills and understanding of sheet metal structure fabrication and repair.

Uses manual and computer numerical controlled cnc metal working machines mills and lathes to manufacture and repair cams gears slots and keyways for aircraft components and se.